After a recent trip to the Poughkeepsie Galleria, I returned home with a pair of new jeans from Old Navy. The High-Waisted Wow Flare Jeans feature a medium wash and are crafted from a blend of materials. The fabric composition includes 69% cotton, 30% recycled polyester, 7% recycled cotton, and 1% spandex, offering a bit of stretch for a flexible fit. The brand offers different inseam lengths for regular, tall, and petite sizes. My pair, being a 0 regular, has a 32” inseam. The jeans are designed with a snug fit through the hips and thighs, flaring out from the knee. The jeans also feature a button front, belt loops, and front scoop and back patch pockets. The button is engraved with “OLD NAVY” and “SAN FRANCISCO CA,” and the zipper below is an antique bronze. The outside stitching blends with the medium wash, making its appearance very subtle.

When I purchased them, the jeans were minimally packaged and folded neatly on a shelf with others of the same fit. They were organized by size, with the smallest sizes on the top shelf and the largest on the bottom. A rectangular adhesive sticker on the left leg indicated the size and inseam, while two paper tags on the belt and right front pocket featured the Old Navy brand and product barcode.

Old Navy emphasizes sourcing sustainable fibers for its clothing, particularly for its cotton products. Since 2022, they have implemented more eco-conscious manufacturing practices including water-efficient production practices and the Mill Sustainability Program. All strategic mills owned by The Gap, Old Navy’s parent distribution center, are obligated to perform under this program to help build a more water-resilient supply chain and improve its social performance. When dyeing and finishing the High-Waisted Wow Flare Jeans, denim specialists carefully oversee the amount of indigo dye used to produce its classic medium wash. The total dyeing process typically takes 30-60 minutes from start to finish. A pre-wash gives the jeans their “one-wash look”, which involves a laundry procedure of washing the jeans in just water. Washwell™, an additional program used to manufacture all of Old Navy’s clothing, reduces the water used in garment dyeing and finishing by at least 20 percent compared to conventional methods.

Old Navy’s transportation system involves a global supply chain, which sources raw materials from various countries including Bangladesh, Vietnam, and China. Based on the product’s tag, the High-Waisted Wow Flare Jeans were made in Cambodia. While the exact manufacturing location is unclear, The Gap primarily operates factories in Kandal, Cambodia according to the Cambodian Human Rights Portal. On average, it takes factories approximately 11-15 minutes to produce a single pair of jeans through the process of harvesting, washing, mixing, and then spinning the synthetic fibers. Sfgate News claims that Cambodian workers earn roughly $70 per month working in these factories. That would mean that a worker earned only $0.073 making my one pair if it took them 15 minutes to produce it.

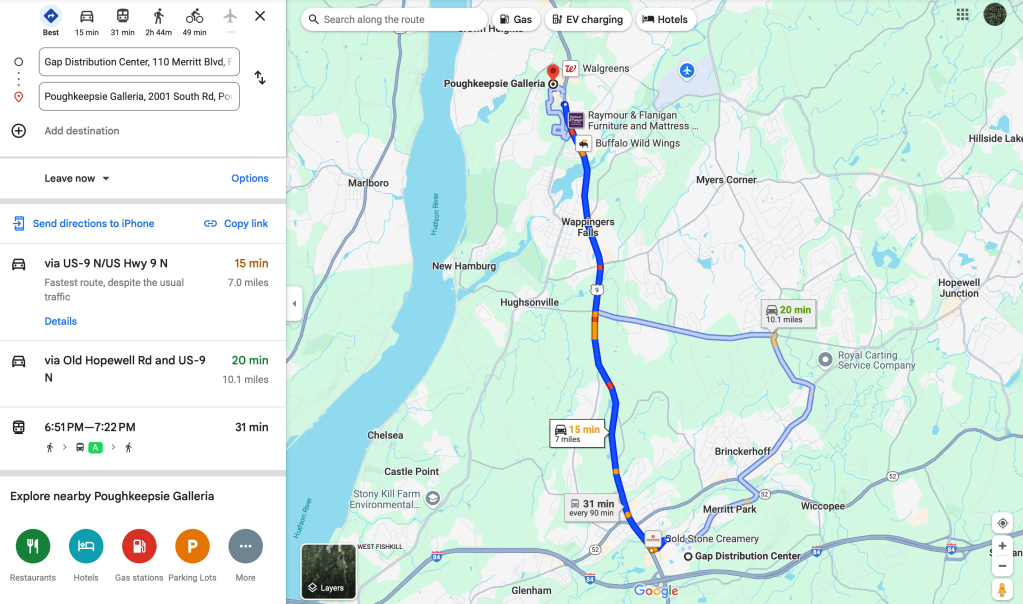

My jeans traveled approximately 8,749 miles to reach Fishkill, New York, home to one of The Gap’s distribution centers in Dutchess County. From there, they were likely transported to the Old Navy store at the Poughkeepsie Galleria. As of May 2024, the average spot rate for dry van trucking in New York is $2.02 per mile. It would cost $14.14 to transport my jeans from the distribution center in Fishkill to the Old Navy in Poughkeepsie since they are only 7.0 miles away from one another.

To ship products efficiently, Old Navy uses a combination of sea, air, truck, and rail transportation, focusing on cost-effective and environmentally friendly methods. It’s unknown whether my jeans arrived in the U.S. by plane or cargo ship. Shipping a 20-foot container using ocean freight, which is the most common method, costs between $2,000 and $4,000 depending on demand, fuel prices, and port fees. If I knew the exact delivery route, I could determine whether they were taken to the distribution center by truck or train. Rail transport typically costs around $0.03 to $0.04 per ton-mile whereas trucking can range from $0.10 to $0.15 per ton-mile.

The journey of these jeans involved a great deal of resources, labor, and time. Learning about the history of my jeans deepened my appreciation for owning them and the privileges I have as a consumer.

Works Cited:

Denimhunters. “How Jeans Are Made: The Pre-Washing Process.” Denimhunters, www.denimhunters.com/how-jeans-are-made-pre-washing/. Accessed 2 Oct. 2024.

Gap Inc. “Gap for Good.” Gap.com, www.gap.com/page/gap-for-good?cid=1086537. Accessed 2 Oct. 2024.

Gap Inc. “Product Life Cycle.” Gap Inc., www.gapinc.com/de-de/impact/esg-resources/governance-and-strategy/product-life-cycle. Accessed 2 Oct. 2024.

Gap Inc. “Water Stewardship.” Gap Inc., www.gapinc.com/en-us/impact/bridging-the-climate-gap/water-stewardship. Accessed 2 Oct. 2024.

Long John. “Jeans Recipe: What Is Needed for 1 Pair of Jeans?” Long John, www.long-john.nl/jeans-recipe-what-is-needed-for-1-pair/#:~:text=An%20average%20factory%20can%20produce,the%20wash%20treatment%20can%20start. Accessed 2 Oct. 2024.

MoverDB. “Container Shipping.” MoverDB, www.moverdb.com/container-shipping/. Accessed 2 Oct. 2024.

Old Navy. “High-Waisted Wow Flare Jeans.” Old Navy, www.oldnavy.gap.com/browse/product.do?pid=8568330020002&cid=3034852&pcid=3034847&vid=1#pdp-page-content. Accessed 2 Oct. 2024.

RSI Logistics. “Comparing the Costs of Rail Shipping vs. Truck Shipping.” RSI Logistics, www.rsilogistics.com/blog/comparing-the-costs-of-rail-shipping-vs-truck/. Accessed 2 Oct. 2024.

SFGate. “Garment Workers Say Gap Aided in Cambodian Strife.” SFGate, www.sfgate.com/news/article/garment-workers-say-gap-aided-in-cambodian-strife-2746484.php#. Accessed 2 Oct. 2024.

Sithi.org. “Garment Factories.” Cambodian Human Rights Portal, www.sithi.org/garment-factories. Accessed 2 Oct. 2024.

I thought it was very interesting how you were able to calculate the price it would cost to transport the jeans from place to place depending on the mode of transportation. I was shocked to see the wages the workers receive! That explains why Old Navy products are on the cheaper side…what I wonder though is if other brands are doing the same thing and up charging the customers when they could be giving their workers a higher wage.